What is a van một chiều lá lật? Flap check valves are usually two-port valves, which means they need 2 openings within the body, one for fluid to enter and therefore the different for fluid to go away. There are varied varieties of flap check valves employed in a good type of application. Flap check valves work mechanically and most don’t seem to be controlled by someone or any external control; consequently, most don’t have any valve handle or stem.

Ball Flap check valve

A ball flap check valve may be a flap check valve during which the closing member, the movable half to dam the flow, is a ball. In some ball flap check valves, the ball elastic device to assist keep it shut. For those styles while not a spring, reverse flow is needed to maneuver the ball toward the seat and make a seal. the inside surface of most seats of ball flap check valves is a lot of or less conically-tapered to guide the ball into the seat and kind a positive seal once stopping reverse flow. Ball flap check valves should be homeward-bound in an exceedingly manner that the direction of raise remains vertical.

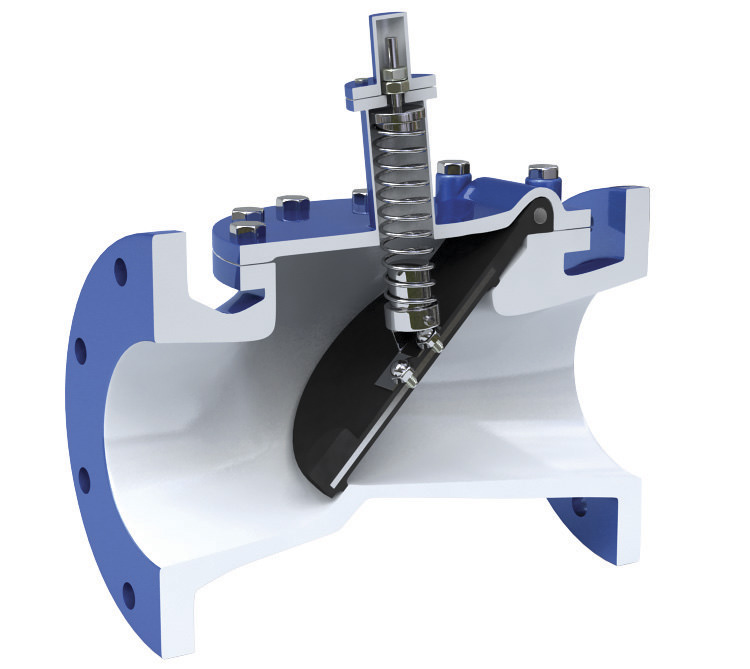

Swing Flap check valve

A swing flap check valve may be a flap check valve during which the disc, the movable half to dam the flow, swings on a hinge, either onto the seat to dam reverse flow or off the seat to permit forward flow. The seat gap crosswise is also perpendicular to the line between the 2 ports or at the Associate in Nursing angle. The force of gravity has a vital role in determining how well a flap check valve will perform. Hence, each location and orientation of those valves should be thought-about for your needed application.

Swing flap check valves ought to be settled in an exceedingly manner that their position permits their disc to be closed freely by gravity.

6 further stuff you ought to comprehend Flap check valves.

- Pipe diameter isn’t the sole thought once it involves the correct size. Application and flow should even be taken into thought.

- Water Hammer may be a pressure surge or wave caused once a fluid in motion is forced to prevent or modify direction suddenly. this may harm the wind, valves, and pumps. the right flap check valve can considerably cut back this condition.

- An undersized flap check valve causes excessive noise, vibration, and high loss in water pressure.

- An outsized flap check valve causes in-depth wear of valves yet as a failure of essential internal elements.

- Size matters! Properly sized flap check valves can add longevity and sturdiness to not solely the valves, but, to pumps and connected elements too.

- Remember to properly size flap check valves by considering gap pressure. this may check that the valve is totally open and supported most fluid flow.

Flap check valves are straightforward valves. They use forward flow to open the valve, then mechanically shut once flow stops, preventing reverse results and creating its manner back through the valve. They don’t need the power to perform, and they don’t need a full ton of attention or maintenance. they are doing get plenty of attention, however, after they slam.

What causes the slam?

A flap check valve depends on gravity and/or reverse flow to shut utterly. chance for flap check valves to slam oftentimes happens at the pump end. once a pump stops, gravity and reverse flow slam the flap check valve shut. as a result fluid is non-compressible, and it creates a pressure or wave (water hammer). The fluid continues to flow back and forth till friction losses cause the wave to settle.

Slamming flap check valves cause serious pressure surges in an exceedingly system that rattle pipes and harm instrumentation. Some individuals assume that’s simply what flap check valves do. “No matter what, they’re progressing to slam.” however that’s simply not the case. Usually, the $64000 reason behind these issues stems from poor size and choice, not the kind of valve itself.

Minimizing Slam Through the correct size

Oftentimes flap check valves are chosen to support the pipe size and therefore the need for the biggest Cv attainable. (CV stands for “coefficient of flow” for valves and demonstrates a valve’s capability for the liquid to flow through it.) in fact, you would like the flexibility to place the maximum amount of fluid through the valve as attainable, right? is sensible, except this utterly disregards the actual fact that flow conditions verify the interior performance of a flap check valve as a result of the disc is directly within the flow path.

If there’s not enough flow to stay the valve absolutely open with the disc reaching the ceiling of the flap check valve, the disc can move up and down, leading to pre-mature wear, the potential for failure, and the next pressure drop.